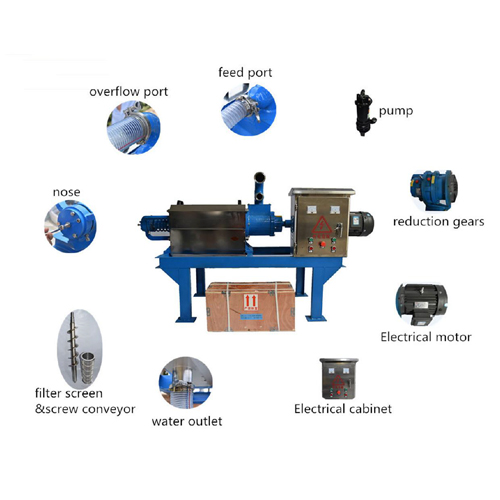

Specification :

| Model | DWAT-55 |

| Machine Dimension | 7.25×2.30×5 feet |

| Motor | 5 HP 3 phase Motor with Gear |

| Processing Capacity | 2 to 3 Ton Slurry Per Hour |

| Material of Construction | All Inner parts made from Stainless steel Outer cover Made from stainless steel constructed from Heavy C Channel Frame Compact and Highly Efficient Design Mesh made from Special Steel Bars |

| Supply | Motor Starter with Voltage Meter |

| Output Material | Dry Material Contains 25-30% Moisture |

Application :

The scope of application is the livestock manure dewatering treatment, including pigs, chickens, cattle and so on. Also widely

used in distiller’s grains, cassava residue, sludge treatment, etc.

Economic benefits :

- Solid excrement after separation is conducive to transportation and higher price for sale.

- After the separation, the excrement is mixed into the grass bran to stir well, it can be made into compound organic fertilizer after granulation.

- The separated excrement can be directly used to improve soil quality, and it can also be used to breed earthworms, grow mushrooms and feed fish.

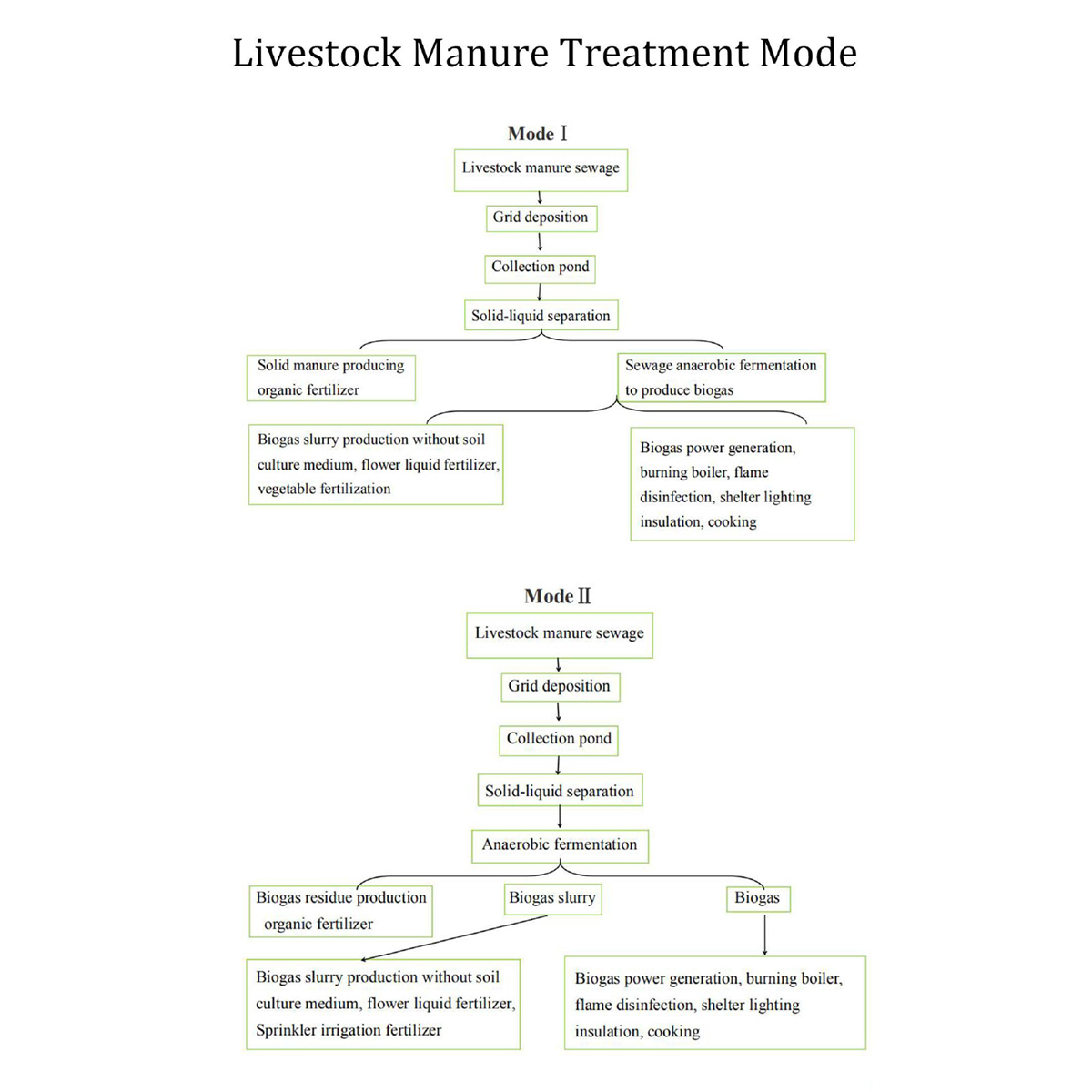

- The separated liquid can directly enter the biogas pool, the biogas production efficiency is higher, and the biogas pool will not be blocked to prolong the service life.